CANADA’S LASER CLADDING & DURABILITY EXPERTS.

When you need durability, laser cladding is the modern ‘go-to’ method to multiply the lifespan of your parts.

With the technology and knowledge of materials increasing laser processing can be used any industry.

Wherever high value components are used, we have techniques to refurbish those components. Cost savings, part availability, and reduced inventory are terms that are used from agribusiness to wine making. The number of industrial applications for laser processing are increasing at a rapid rate.

APPLICATIONS >

MATERIAL EXCELLENCE, EXPERTLY TRAINED STAFF & THE HIGHEST QUALITY PRODUCTS.

Services

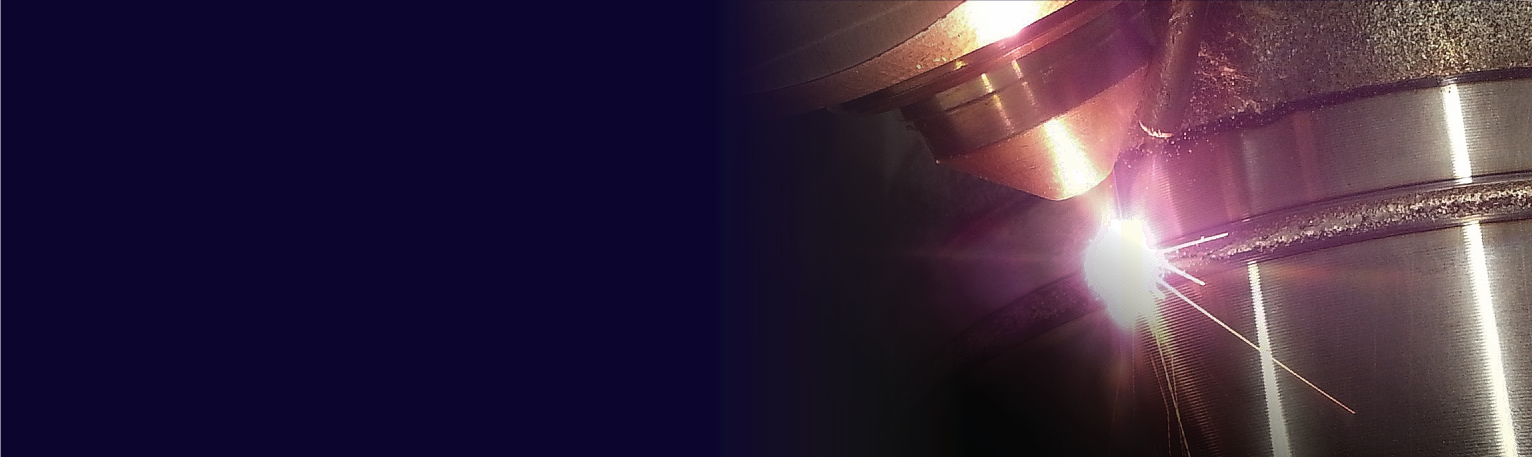

Laser Cladding

Laser cladding is a process to apply metal coatings using a precision laser as a heat source. These powders can be a variety of different materials that are used to protect, repair and increase the life span of parts.

LEARN MORE >

Laser Welding

Welding with a laser allows the joining of components with little extraneous heat input. The autogenous process (no filler material used) has a very small heat affected zone so sensitive geometry is preserved.

LEARN MORE >

Laser Heat Treating

Surface hardening using a laser is used to improve the wear resistance of the surface of a part without affecting the tougher interior. We have the ability to perform laser hardening on selective internal or external surfaces.

LEARN MORE >

Grinding

Our CNC Universal grinder has a BIG working envelope and can handle long parts with a large thru-bore chuck. To finish off those laser clad bores, our internal grinder has a long spindle and large work head to accommodate a wide range of components.

LEARN MORE >

Applications

We recognize that time is valuable no matter the industry.

As a dedicated shop for laser cladding, we have control over our schedules and can give our customers realistic and reliable turn-around times for your jobs.

GET RELIABLE DELIVERY >

WE HAVE A STREAMLINED REBUILD PROCESS TO REDUCE COST.

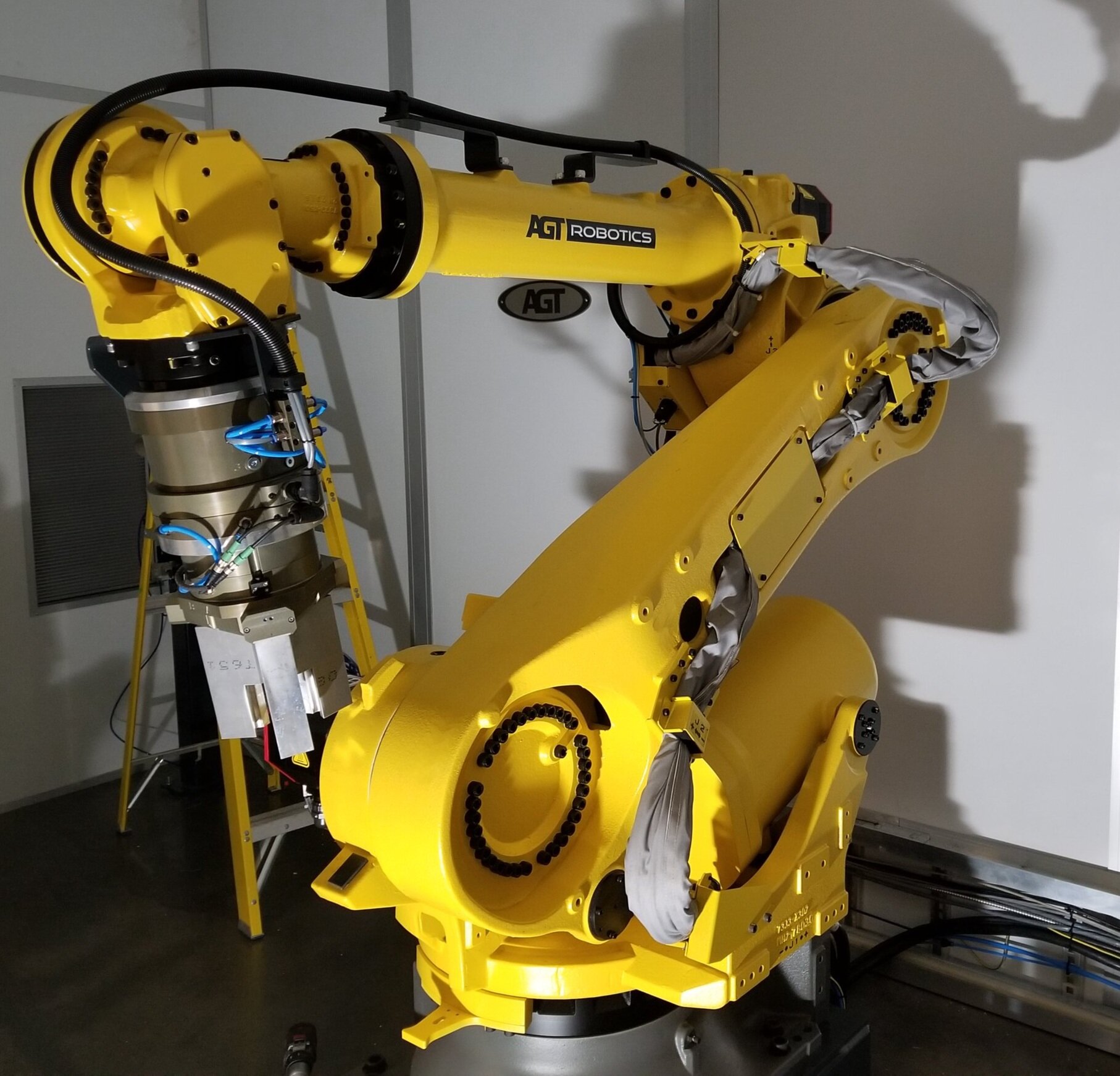

Technology

A commitment to technology development ensures a stream of new solutions for our customer’s problems.

Our highly automated facility, in house materials laboratory, and collaborations with institutes of higher learning, allow us to push the boundaries of traditional thought. Our customers see it as faster turn around, high quality, and better preforming components.